I have wanted and needed a means to smoke bacon, ham and cheese for as long as I can remember. I have finally managed to assemble a good working system.

I have a shop full of tools of every sort because I repair houses for a living.

I also had leftover from a job some clay flue liner intended for chimney liners. I cut a section to 12 inches and cut a little door into the side at one end.

I used a piece of steel rain gutter downspout for a pipe to convey smoke to my grill.

When I made a new burner for the grill,

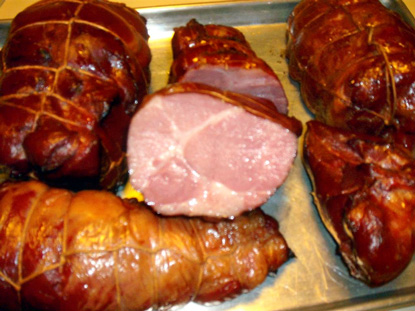

I replaced the gas orifice with a much smaller one so that i could control a lower heat in the grill because I wanted to be able to apply warm smoke for a long time to get results like this

and this.

I may have to stop here and start a new chapter.

Editor’s Note: Ross used a special high temperature alloy solder for his copper pipe. For a safe homemade smoker, do not use common solder.

Do you have a recipe post or kitchen-related story to share on the Farm Bell blog? See Farm Bell Blog Submissions for information, the latest blog contributor giveaway, and to submit a post.

Want to subscribe to the Farm Bell blog? Go here.

Shelley says:

Oh Ross you may have just saved my dead gas grill. Is that homemade burner made from copper pipe? I love this idea.

On December 26, 2011 at 5:01 am

Miss HomeEcs Daughter says:

Ross, this is better than Alton Brown’s…Yes you must continue on with instructions.

On December 26, 2011 at 7:43 am

Jerry says:

I see that it appears you soldered the copper pipe. As solder has a very low melting temperature, seems to me you’d have to be very VERY careful on the heat, otherwise the entire assembly melts and you have a dangerous situation on your hands, especially right up against the house. Am I missing something here?

On December 26, 2011 at 9:20 am

Ross says:

Shelley, Yes the burner is made from copper pipe or more properly copper tubing. The joints are made with Harris Blockaid silicon/phosphorous/copper brazing alloy available at welding supply centers. I used the old venturi tubes. I simply duplicated the size of the burned out old burner.

These are links to videos of cutting a pork butt and applying the cure mixture to the meat.

http://s1112.photobucket.com/albums/k482/nansssor/?action=view¤t=2011_1220cardoldcameranew0003.mp4

http://s1112.photobucket.com/albums/k482/nansssor/?action=view¤t=2011_1220cardoldcameranew0002.mp4

In few minutes I will start a video for tying the meat into round shapes for smoking.

On December 26, 2011 at 10:21 am

CindyP says:

What temp are you smoking the meat at? Regular grill orifices will go down to 200, which is the norm for smoking meat.

On December 26, 2011 at 10:53 am

CindyP says:

I found the MSDS sheet on this. It says it’s not flammable. http://www.ausweld.com.au/wp-content/uploads/Material-Safety-Data-Sheet.pdf

On December 26, 2011 at 11:02 am

Ross says:

The cure that I used for this meat was made with canning salt (http://www.sausagemaker.com/11000instacureand153no11lb.aspx )This curing mixture. Sugar and molasses. I use Two tablespoonfuls of salt a half teaspoon of Cure#1 a tablespoon of sugar and a half of molasses and just a little water. The curing time in two weeks in the fridge in a big plastic bag and the meat is vigorously moved around in the bag once each day.

On December 26, 2011 at 11:22 am

Ross says:

Cindy I modified the orifice and can throttle down to about 100 with the top closed tightly and if I prop it up an inch even a little lower than that. For cheese of course you don’t want any heat. That is when the grill burners stay off and just the smoke is used. I control the air flow to the wood burner very closely and allow only a smolder and no flames. The wood lasts longer that way also.

On December 26, 2011 at 11:28 am

Ross says:

Jerry , The solder used is High temperature alloy that melts at about 1100 F. Used for air conditioning pipes. The grill is about six feet from the house cantilevered out over the gravel below. A grease flare up is more dangerous than an open gas orifice. More fuel and no control.

On December 26, 2011 at 11:33 am

Jerry says:

Cindy, it’s wasn’t anything flammable that I was concerned with. It was common low temp solder that would melt, thereby dislodging the pipes and creating a hazardous situation.

But now that we know he’s using a special alloy instead of low temp solder (as is normally used on water pipes etc) we’re good to go!

On December 26, 2011 at 2:06 pm

Ross says:

Jerry, It is rather amazing how cool the burner stays. I temporarily blocked some of the burner holes with masking tape in order to increase the flame size in the rest of the burner. After several sessions the tape is still in good shape. Modern plumbing solder melts at about 375 and even then it is a struggle to dismantle plumbing assemblies. The problem I am working on now is making new venturies.

Ross

On December 26, 2011 at 3:28 pm

Ross says:

CindyP, To answer your question about smoking temperatures I try to slowly increase the working temp from cold to about 175 to 200. If it gets too hot the fat melts out of the meat. When the internal temperature of the meat hit 155 I turn the gas off and let the smoke fire burn out. I get no heat from the smoke fire.

Ross

On December 26, 2011 at 3:32 pm

Jerry says:

Ross, I know that typical burners tend to stay “relatively” cool depending on the application. Should something fall down into the burner and prevent the flame from going straight up however, that’s where a problem could occur should anyone use the incorrect type of solder. Just wanted everyone to know not to use common waterpipe solder for this application.

On December 26, 2011 at 5:28 pm

Ross says:

Jerry as you probably know there is a grate just above the burner in all grills that is covered with some type of lava rock or ceramic material to change the clear flames of the propane fire to infrared to cook the meat. If you have ever soldered plumbing lines then you know that fittings two or three inches from the joint being soldered are completely solid. Even when soldering a Tee fitting each leg hardens when the torch is moved to the next joint.

I guess that what I tell you next will trouble also.

When I change the orifice size in a gas jet I solder the orifice with lead free solder and redrill it with the bit size that I want. There is no flame near the orifice and therefore no excess heat.

On December 26, 2011 at 6:06 pm

Jerry says:

My propane grills don’t have lava rock, or anything else. I often toss in some wood for flavor however. Sometimes the ashes get to the point that I must clear around the burners for safety.

On December 26, 2011 at 7:52 pm

Ross says:

That is interesting Jerry. What kind of wood do you prefer for smoke flavor?

On December 26, 2011 at 8:52 pm